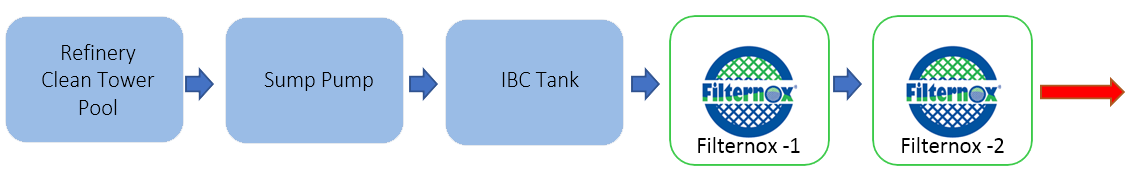

Filternox® engineering and test team conducted filtration tests at a local food company’s refinery clean tower point in October 2020. Tests were carried out with serially connected Filternox® NTU Terminator filters at flow rates of 2, 3 and 5 m3/h and under 2, 2.6 and 2.7 bar pressure.

Flow Chart

Sample and System Images

|

|

| Pic 1. Filternox pilot filtration system | Pic 2. Left to right – Filter-1 inlet, Filter-1 outlet, Filter-2 outlet water samples |

|

|

| Pic 3. Filter-1 and Filter-2 drainage water samples | Pic 4. Filter-1 drainage tank |

Conclusion and Evaluation

In the filtration tests performed with the filtration of Filternox® NTU Terminator filters;

At Refinery Clean Tower Point:

- TSS removal was achieved on average of 47% in one stage and 67% in two stages.

- Turbidity removal was achieved on average 56% in one stage and 73% in two stages.

As a result of the filtration to be performed in the cooling line with Filternox® NTU Terminator filtration system;

- Lifetime of the tower filling will increase

- The amount of chemicals used in the system will be reduced

- The amount of tower blowdown water will be reduced

- Cooling efficiency will be increased

- Unnecessary stops / work interruptions will be prevented

- Operation, maintenance and energy costs will be reduced

- The cooling line will be protected from particles

With all of these mentioned benefits, cooling efficiency is increased incredibly.