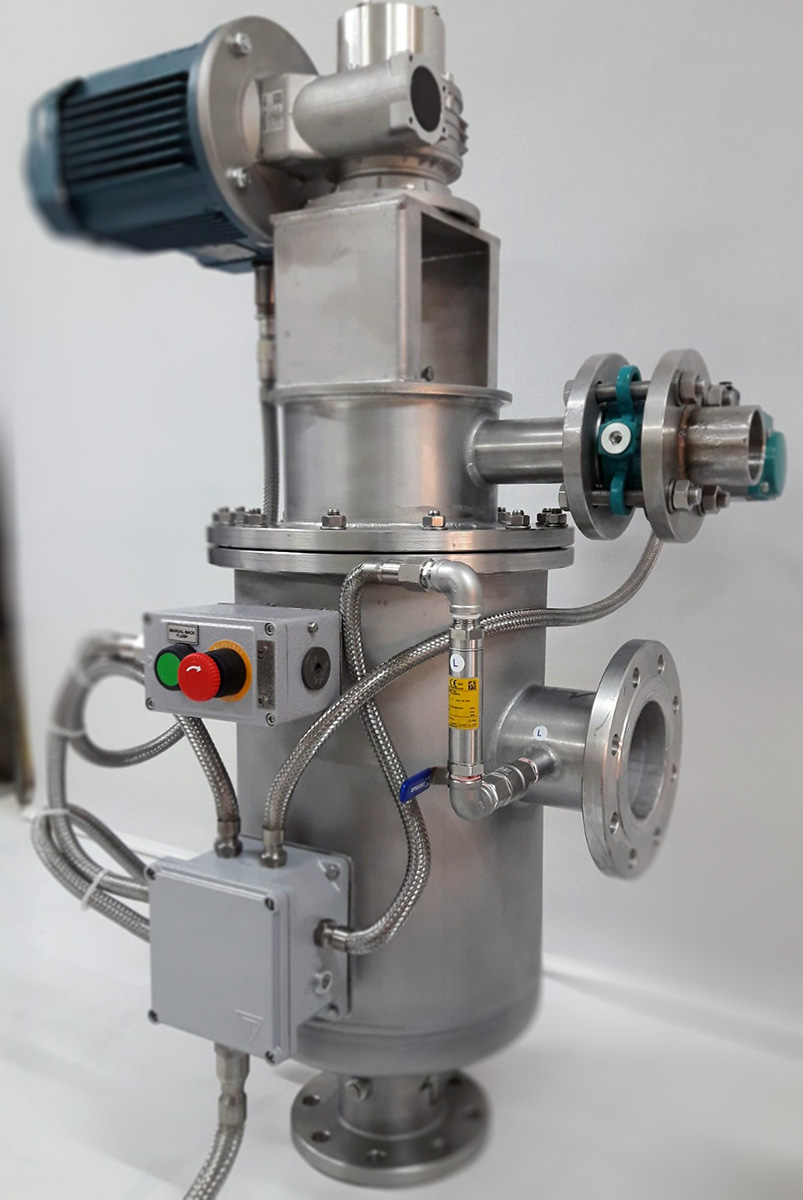

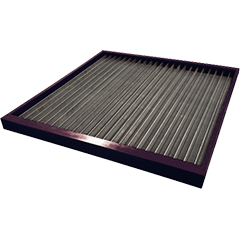

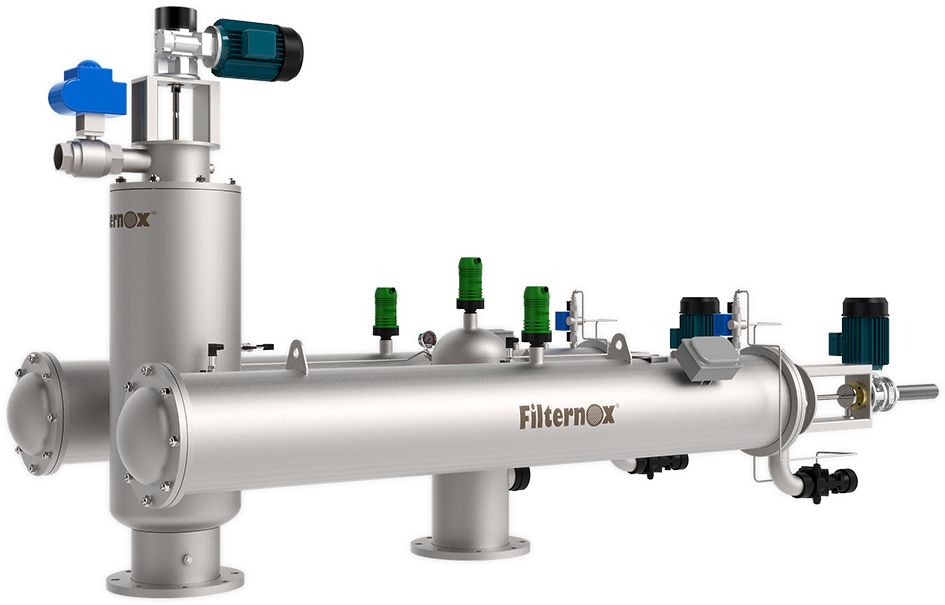

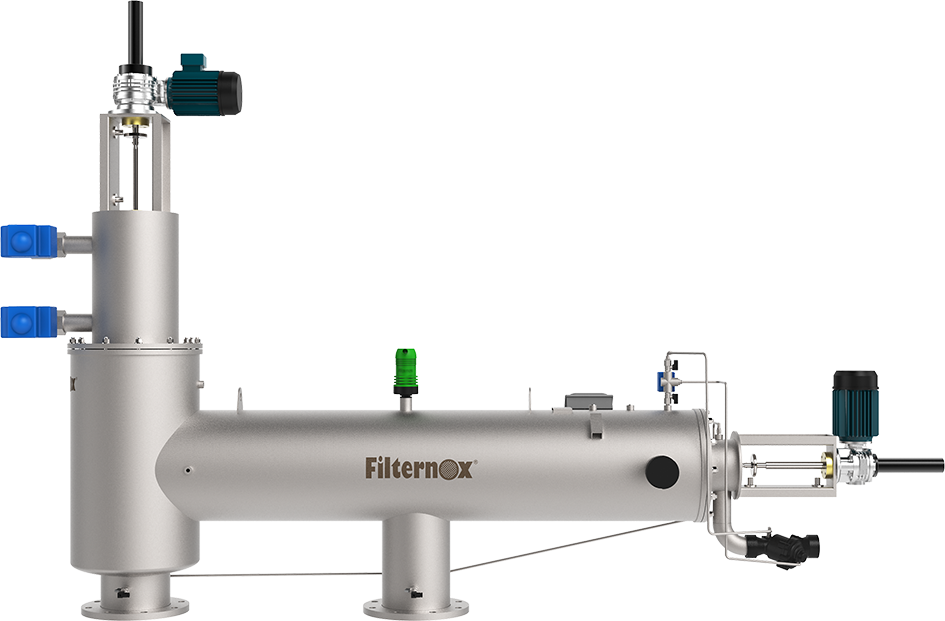

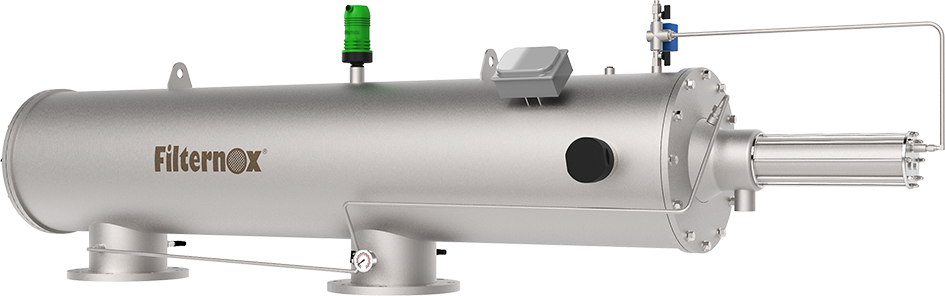

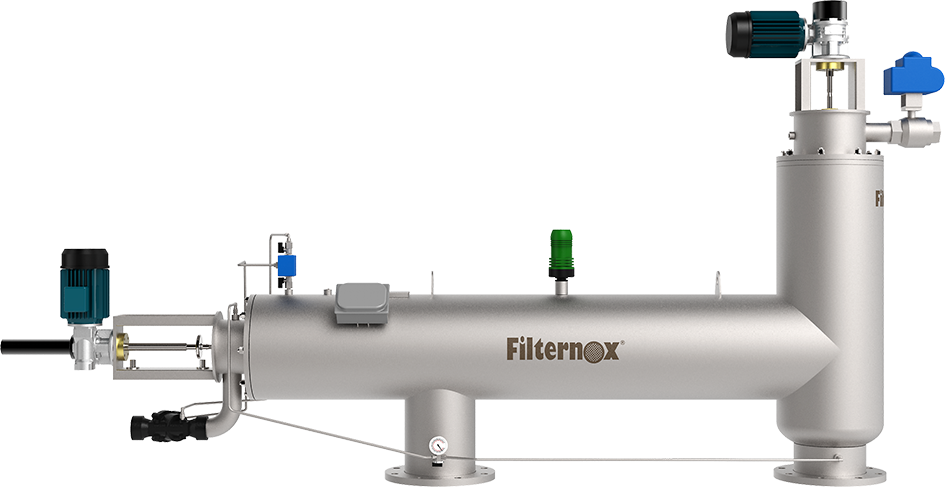

The Automated and Intelligent Way to Recover Gold Dust in Jewelry Production: PATENTED Filternox Self-Cleaning Filters

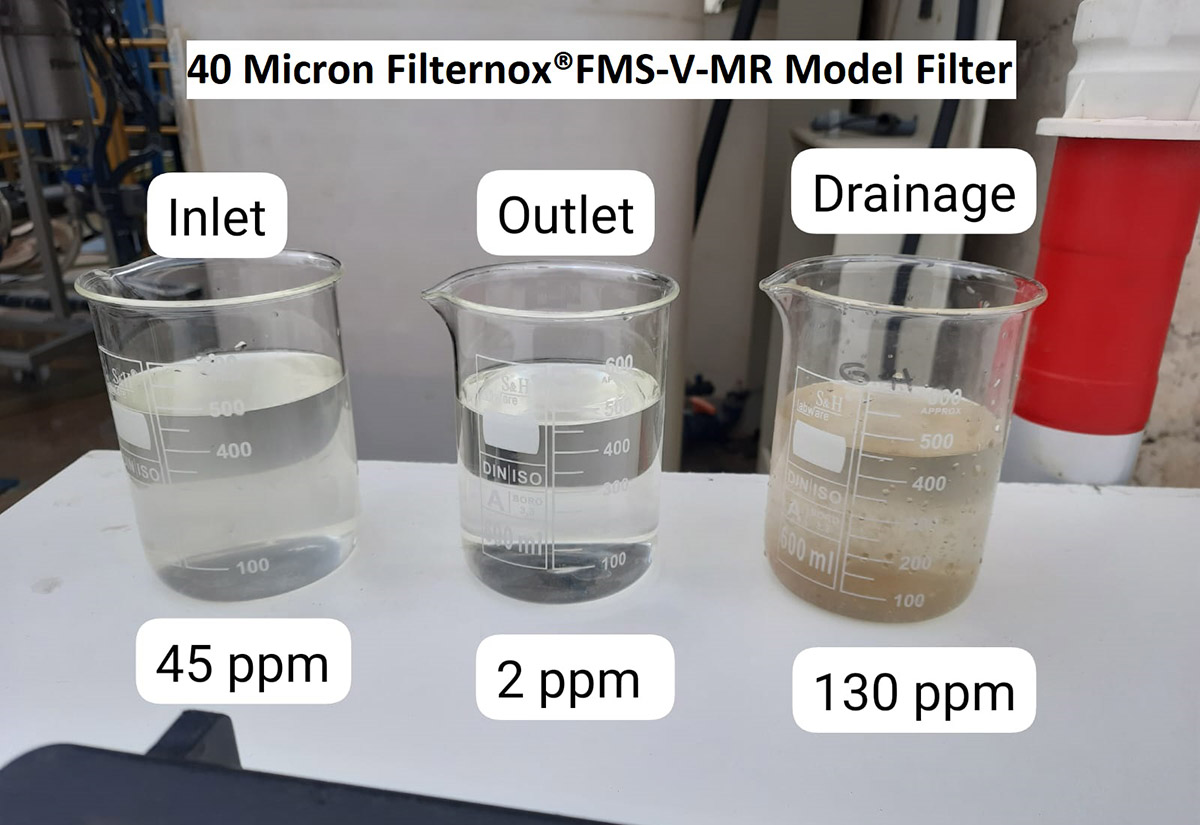

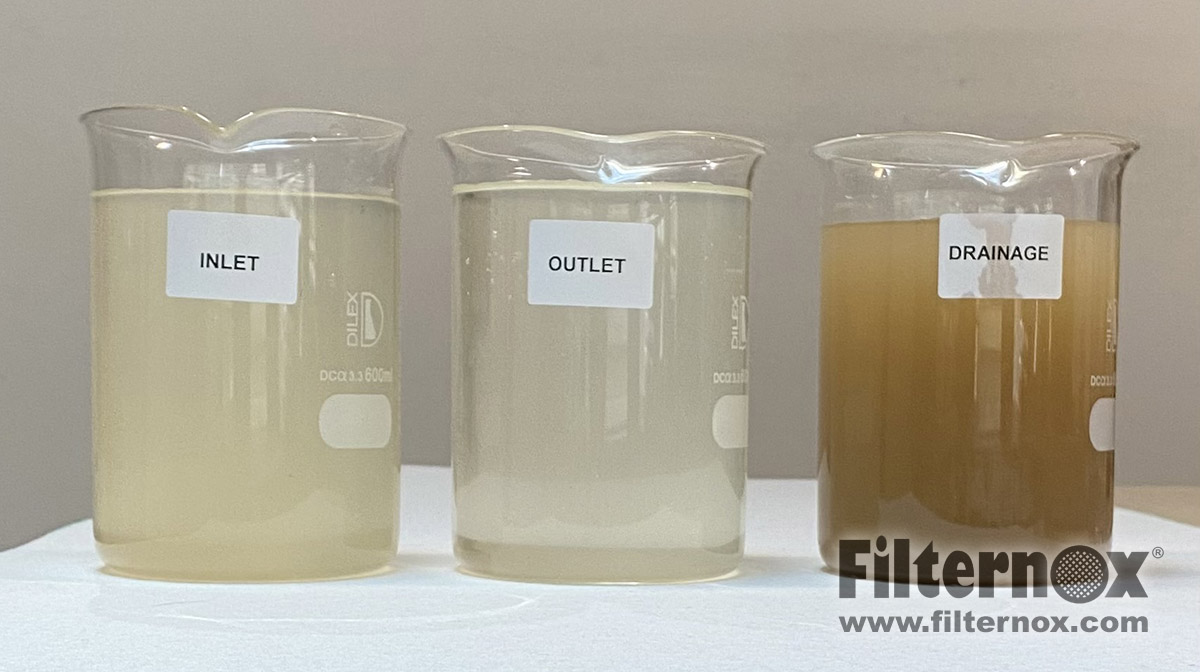

In gold jewelry production, maximizing the recovery of valuable gold dust during the final washing stage is crucial. Filternox® filtration systems are specifically designed to help gold jewelry manufacturers efficiently recover up to extra 20 grams of gold dust from every 1 kg of gold processed. This advanced system not only optimizes recovery but also provides a range of additional benefits, including reduced downtime, water and labor savings, lower outsourcing costs, improved worker efficiency, and enhanced product quality.

Let’s explore how Filternox® filters can revolutionize your gold dust recovery process and enhance overall production efficiency.

Key Benefits of Filternox Filters for Gold Dust Recovery

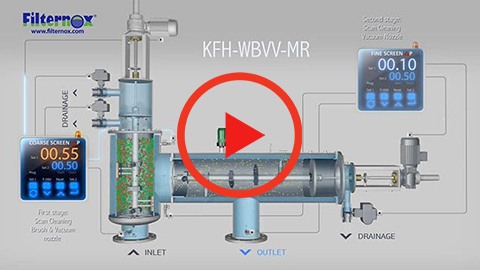

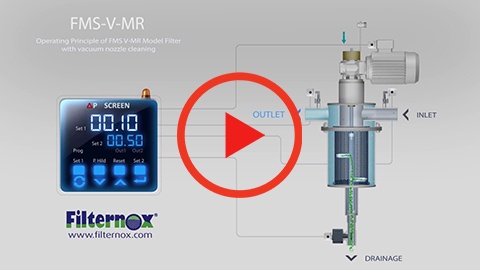

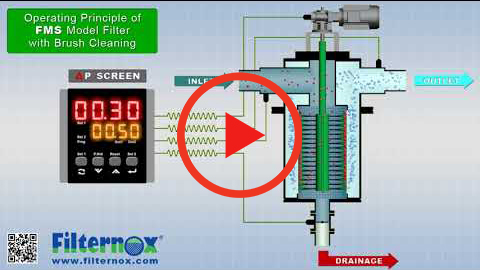

Automated System: With its self-cleaning feature, the need for maintenance and cleaning of the filters is minimized, ensuring an uninterrupted production process. According to the size of the business: It prevents an additional 500 to 750 hours of labor per year.

Reduced Downtime: Compared to traditional systems, it allows for continuous production with less time loss. According to the size of the business: It prevents 500 to 750 hours of downtime per year.

Water and Labor Savings: The need for frequent water changes is reduced, resulting in significant savings in both water and labor costs. According to the size of the business: It provides water savings of up to 300 tons.

Lower Outsourcing Costs: The filtering process minimizes the presence of gold dust in wastewater, reducing the need for outsourcing. According to the size of the business: It reduces the external services and associated costs for the RAMAT process by 75%.

Enhanced Product Quality: Continuous filtration decreases the risk of contamination in products, ensuring higher quality.

Filternox’s self-cleaning filters revolutionize gold dust recovery in jewelry production, providing businesses with efficiency and cost advantages. If you’re looking for an intelligent solution for gold dust recovery in pursuit of a sustainable future, Filternox® filters are the right choice for you!

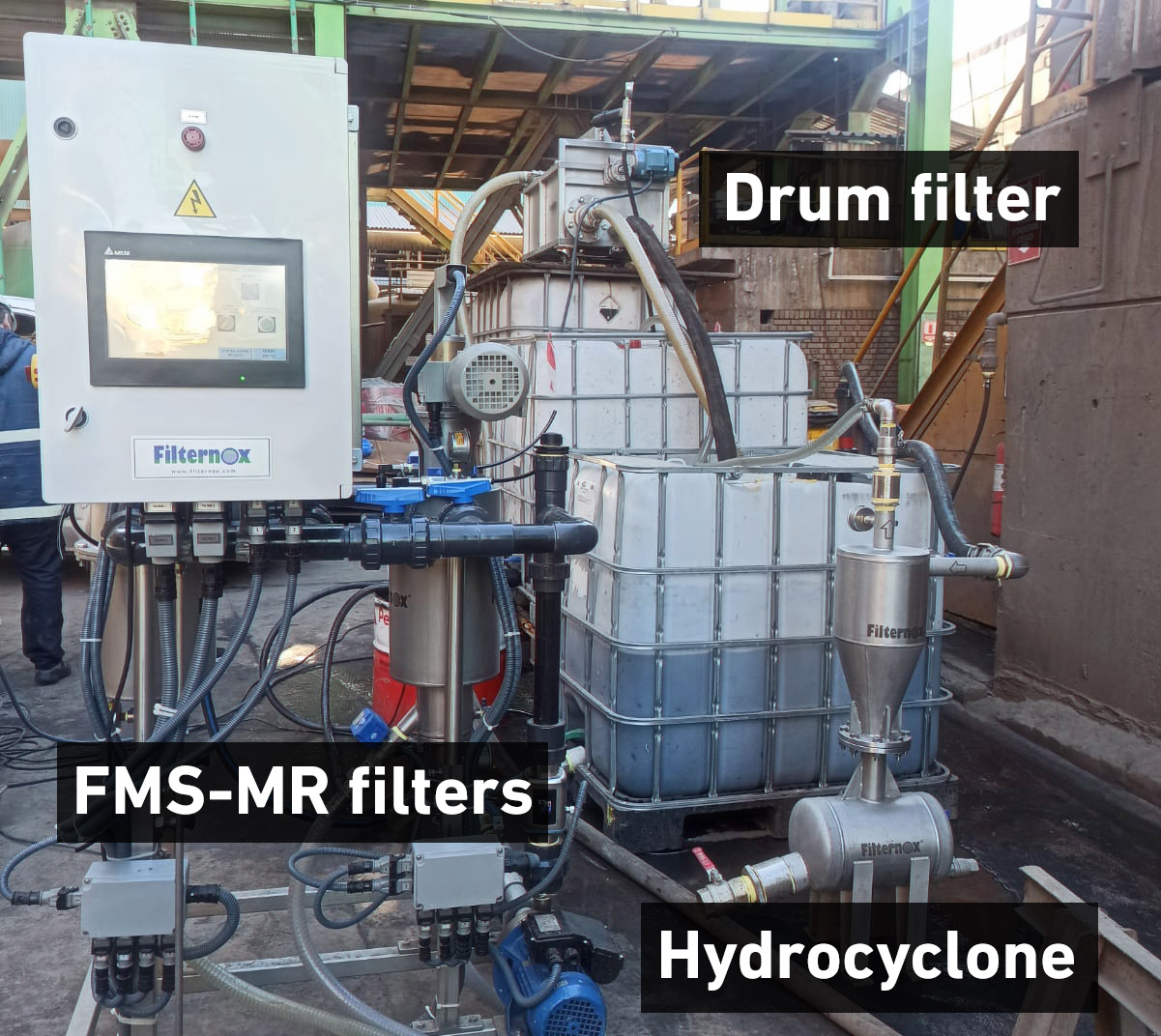

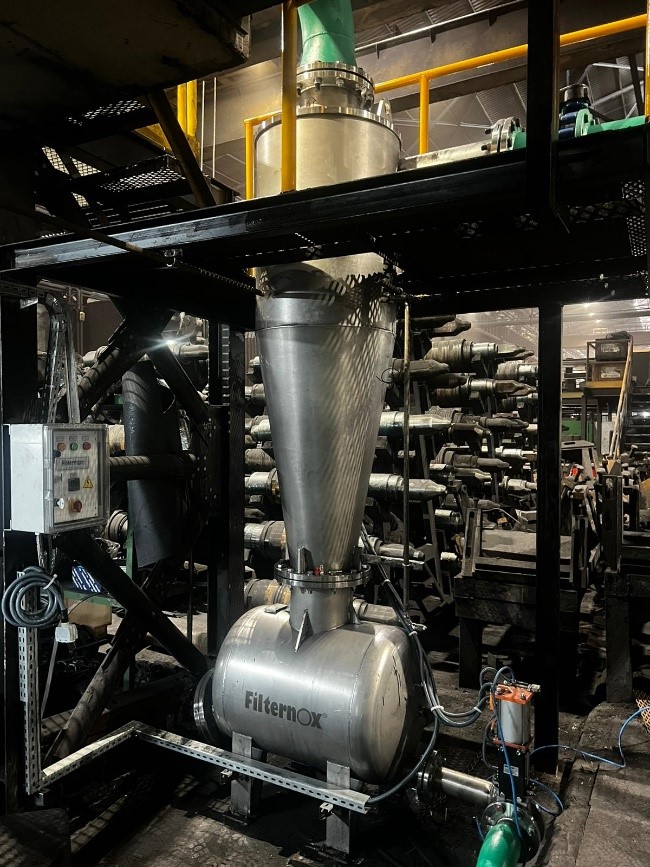

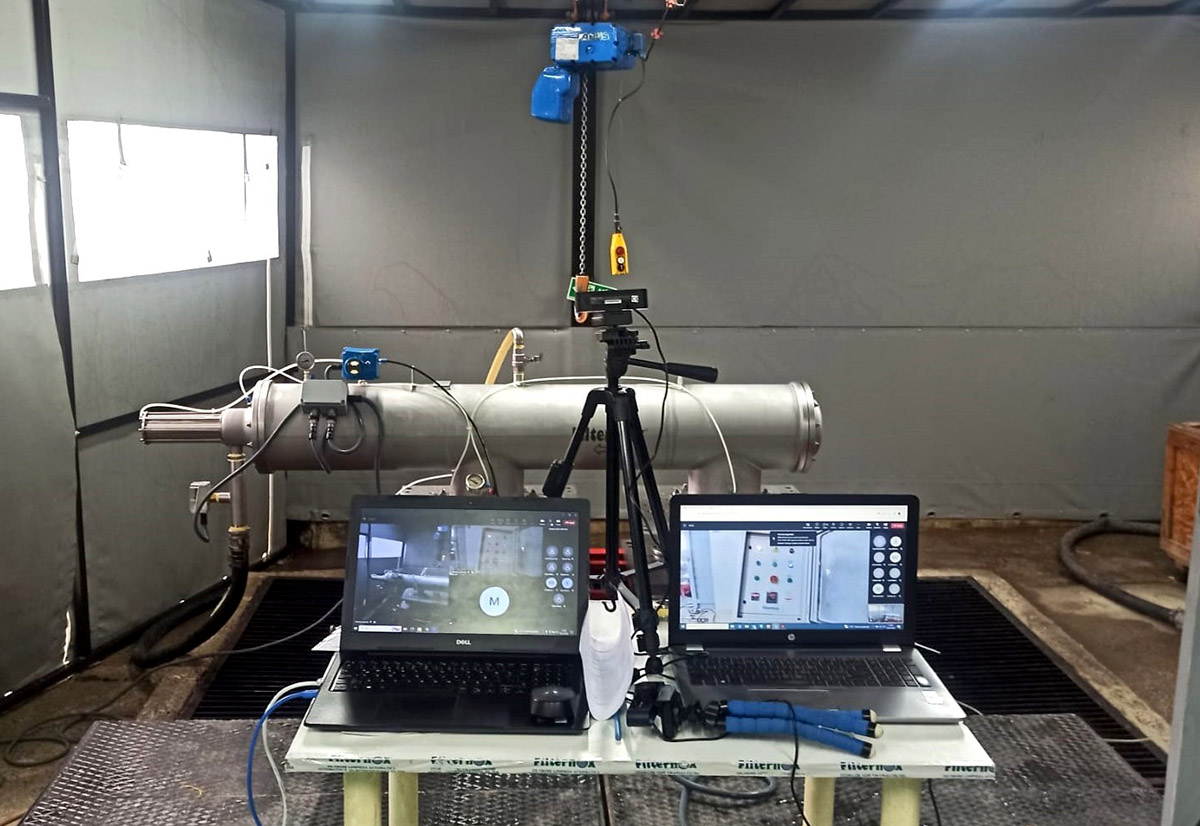

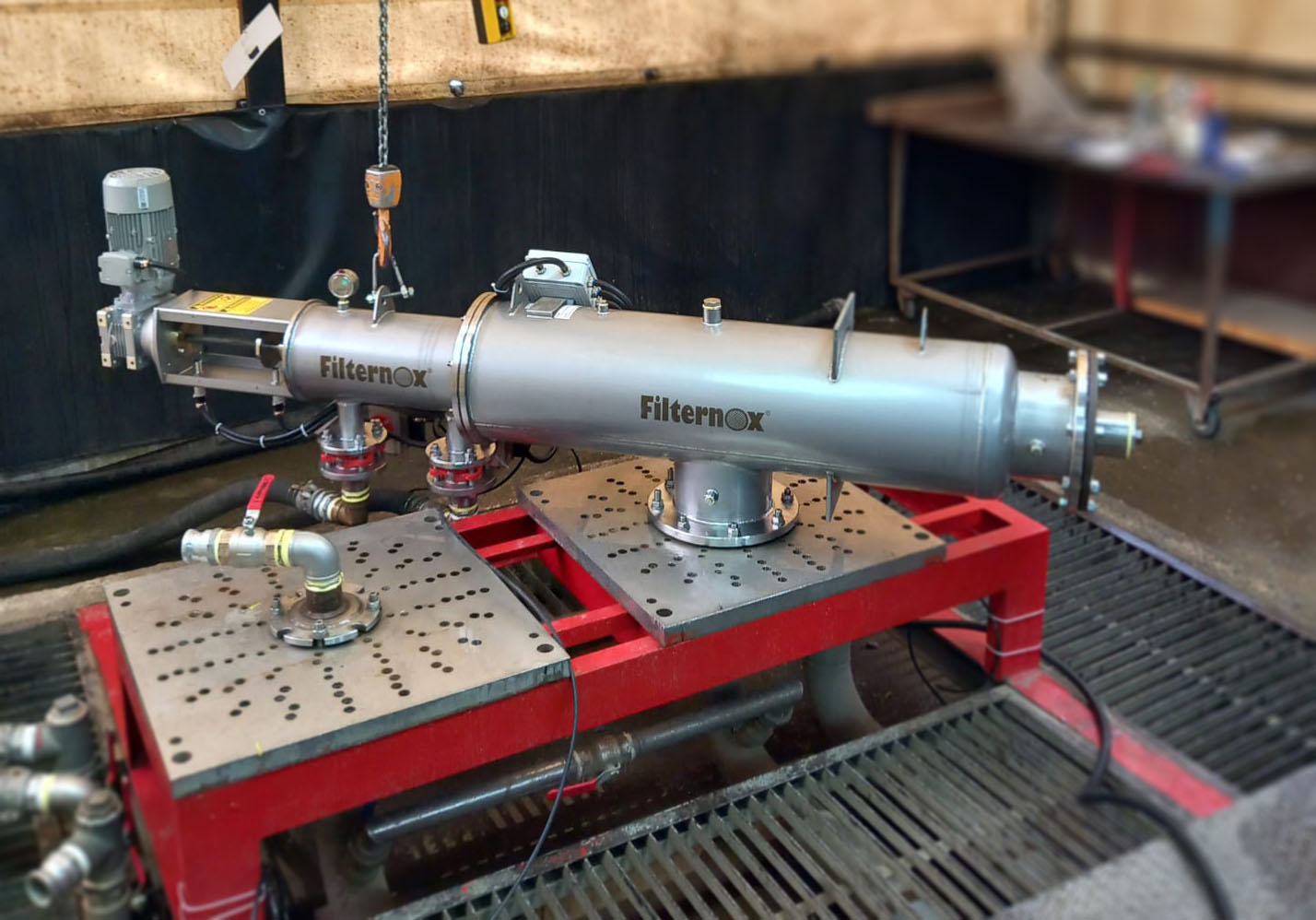

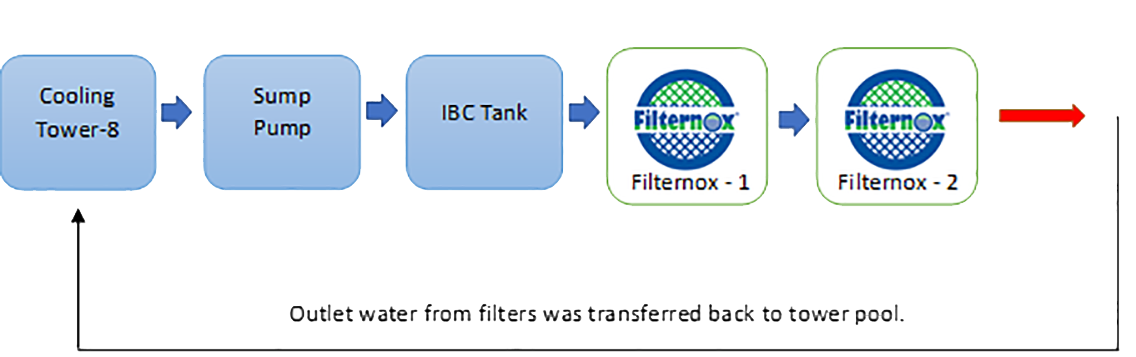

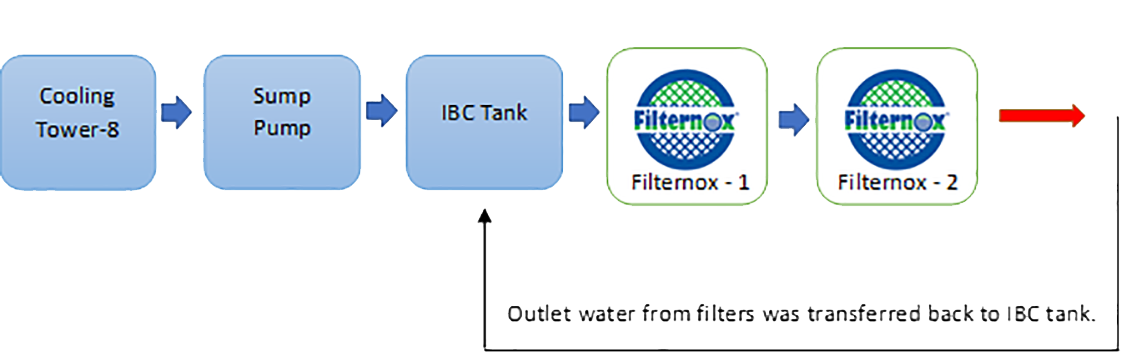

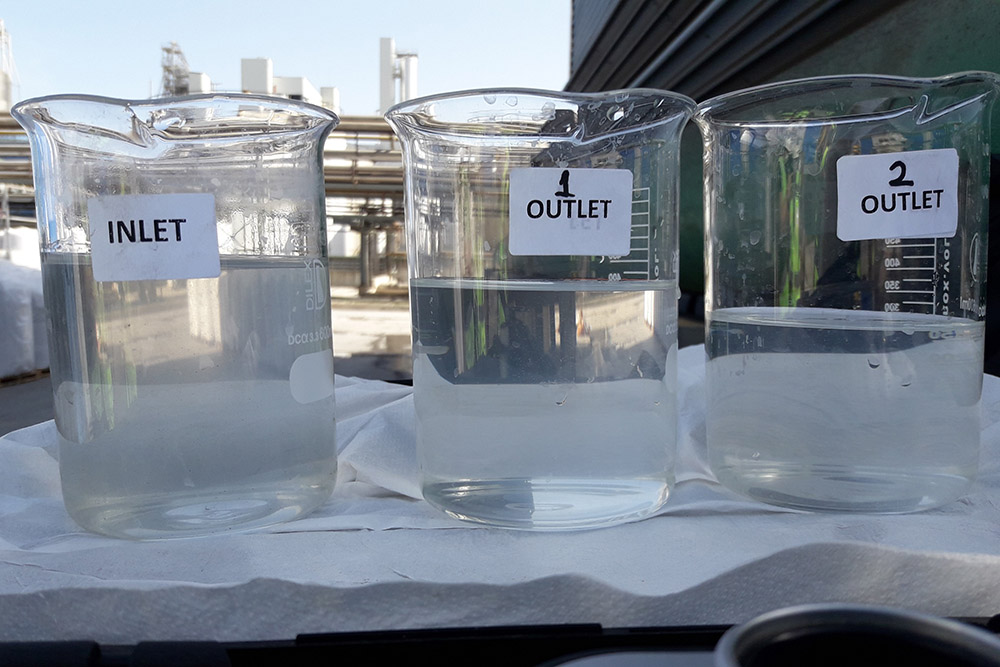

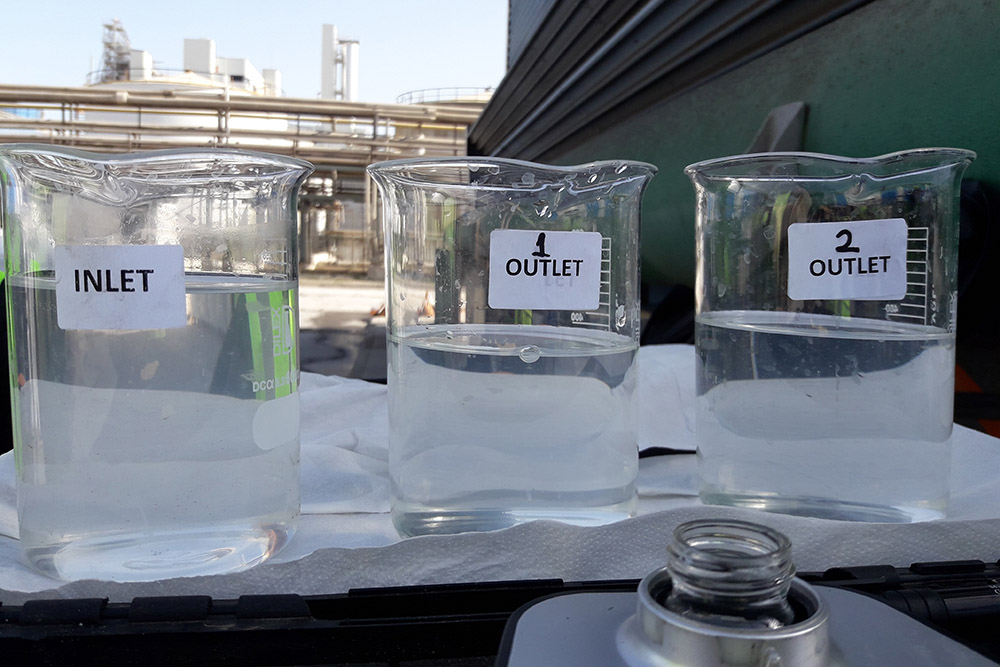

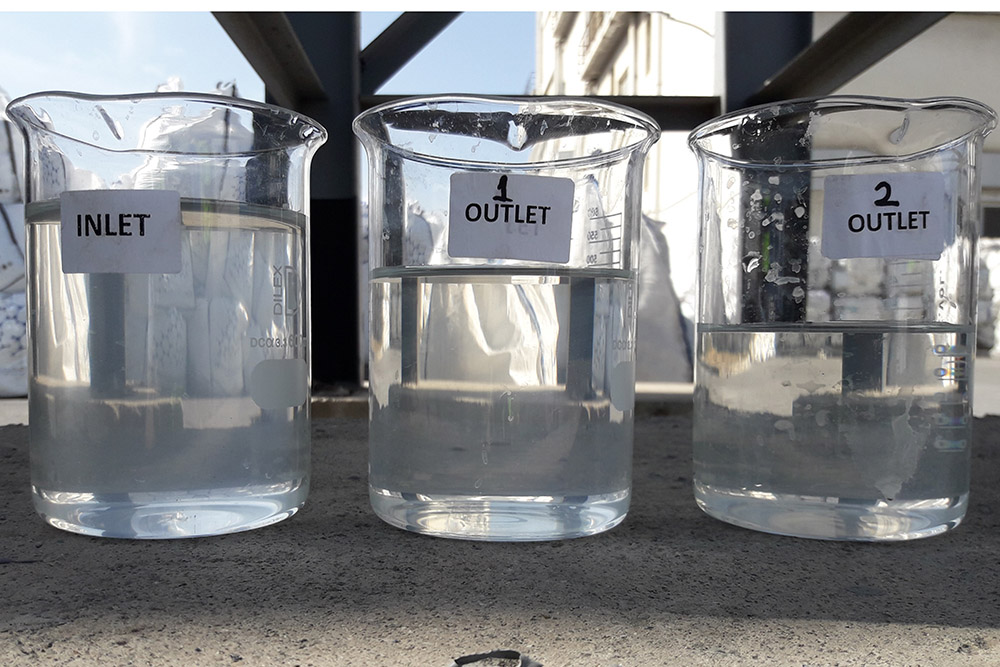

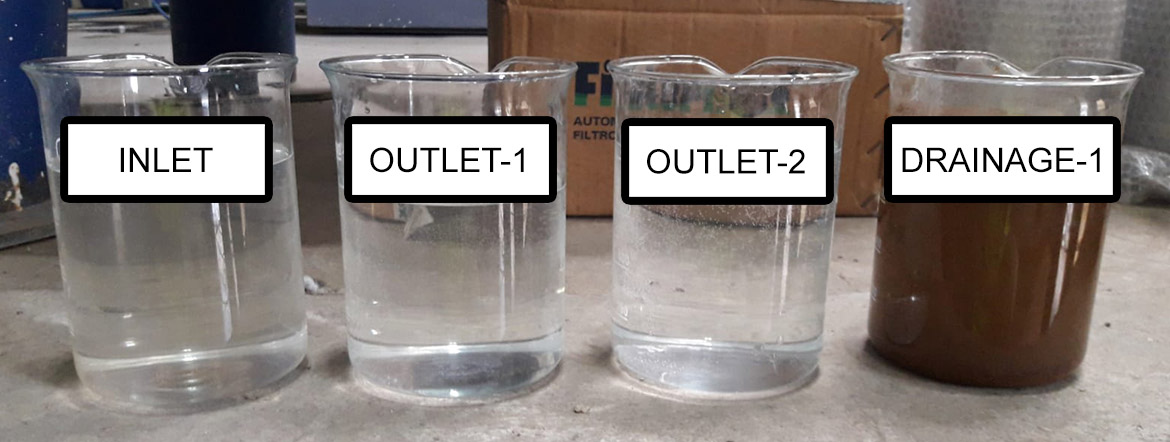

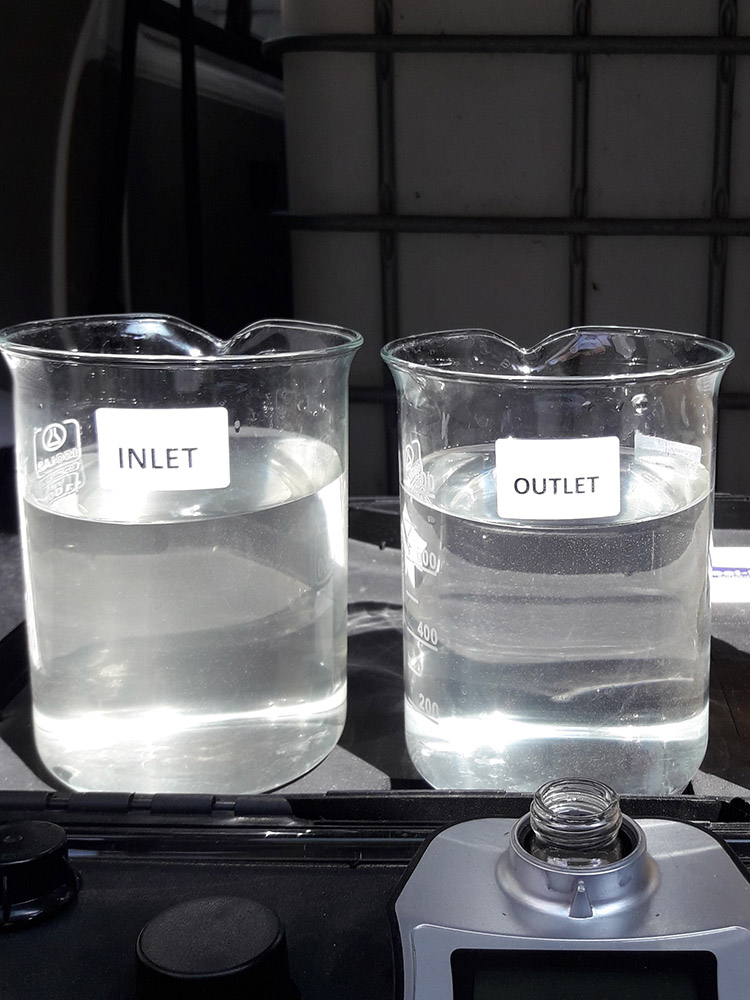

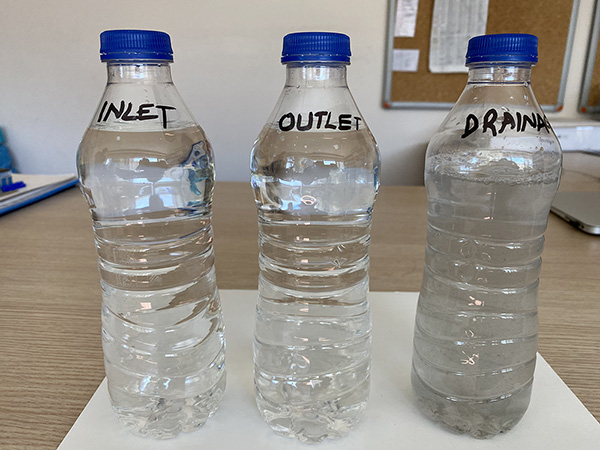

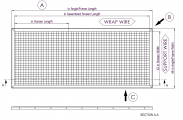

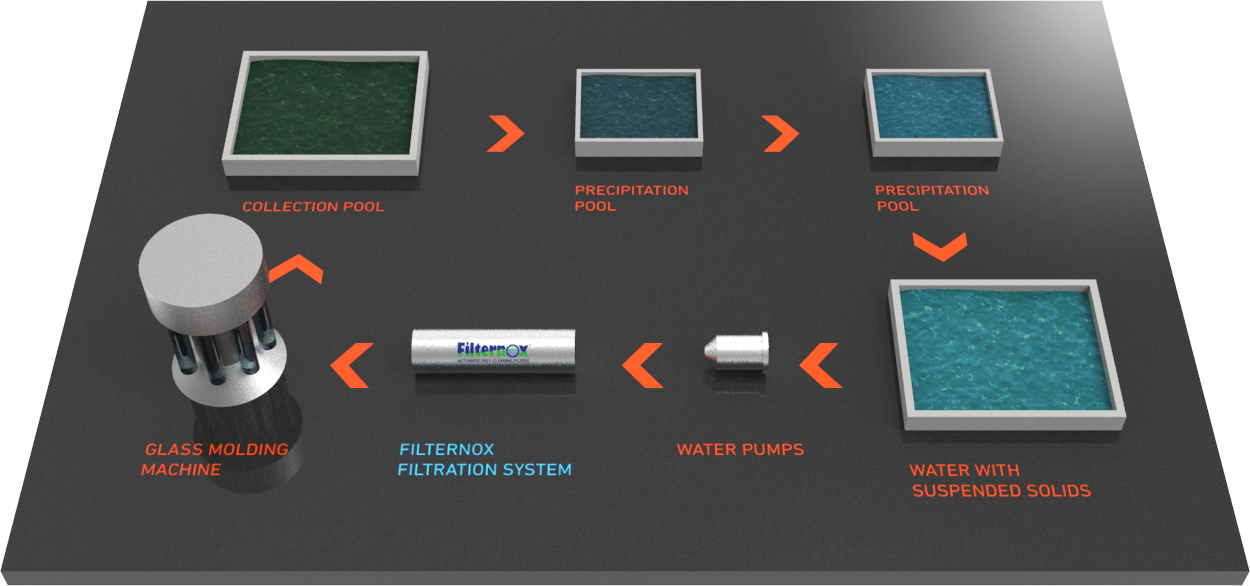

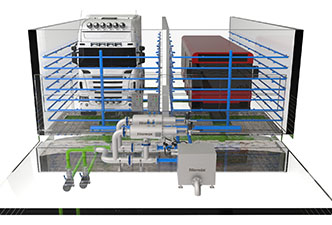

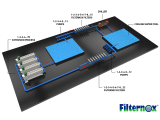

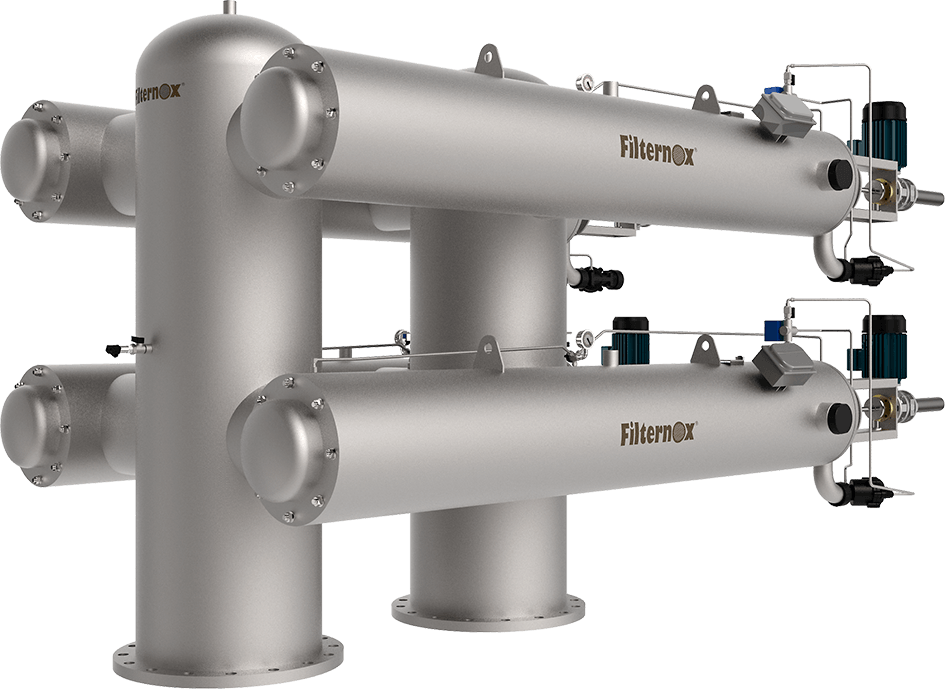

The calculations are based on the sample process data gathered from a system with three (Rough-Medium-Final) washing tanks, shown below.

Factory

Factory

factory.

factory.

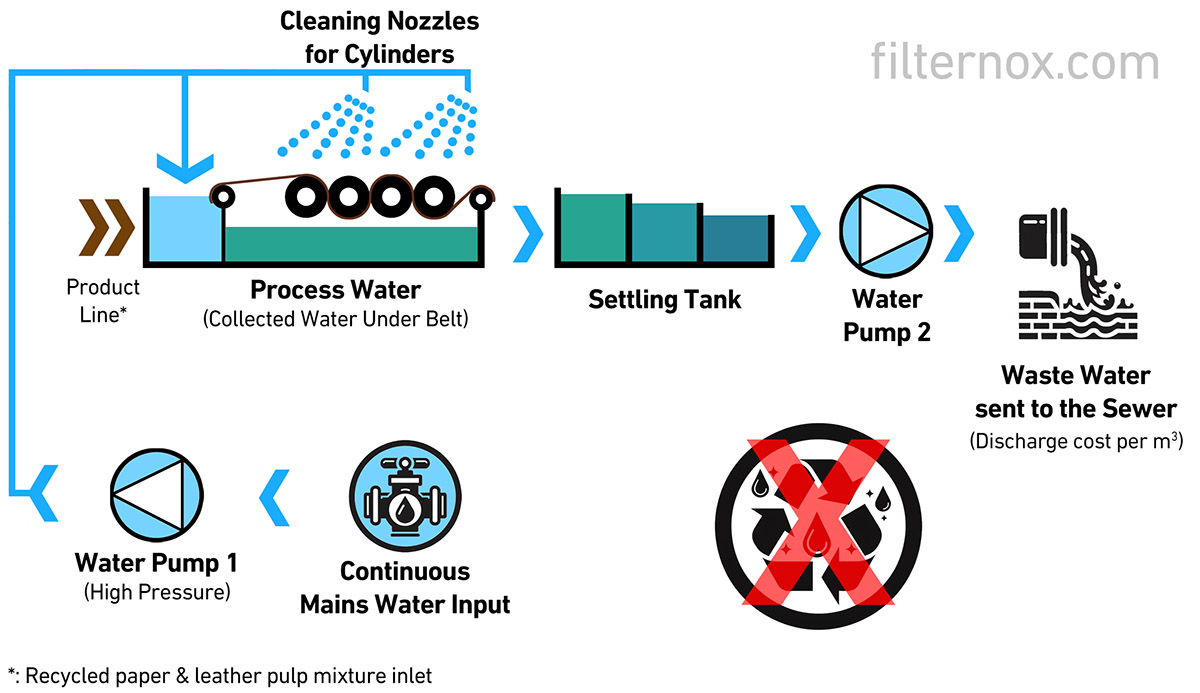

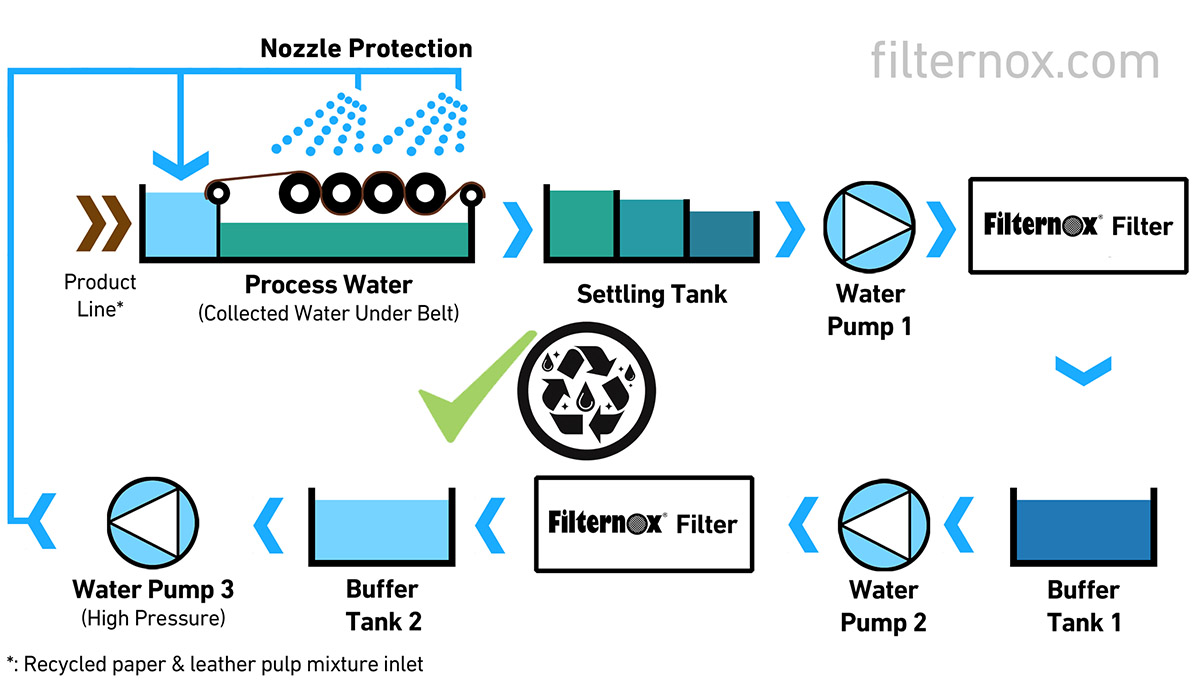

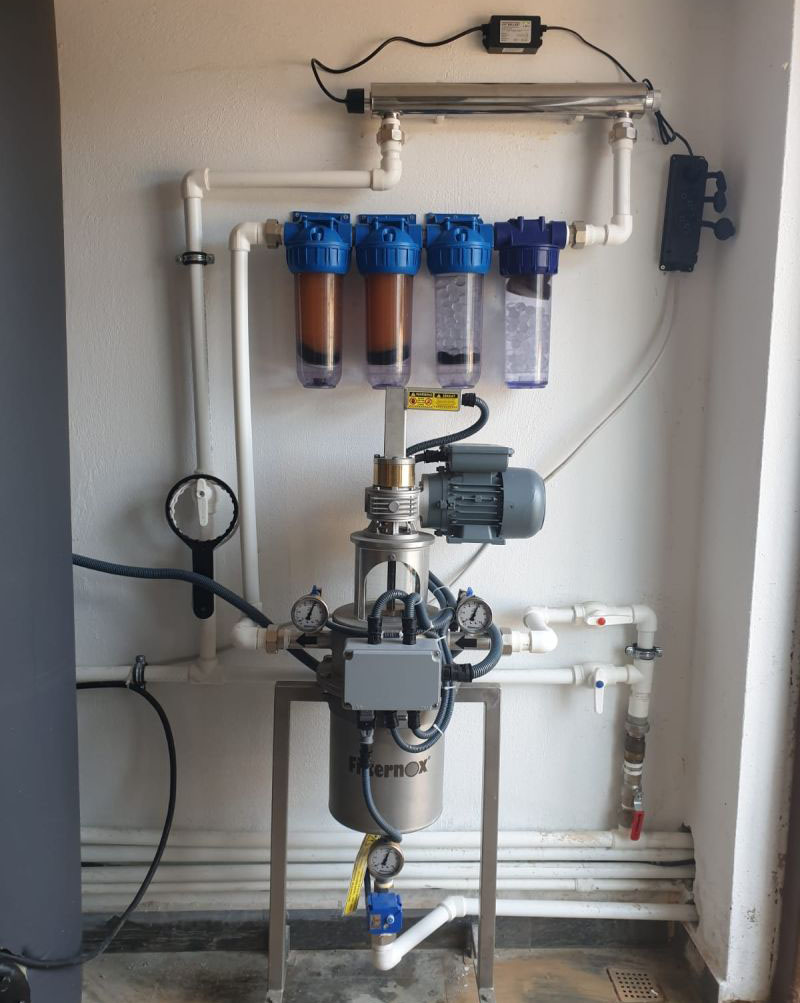

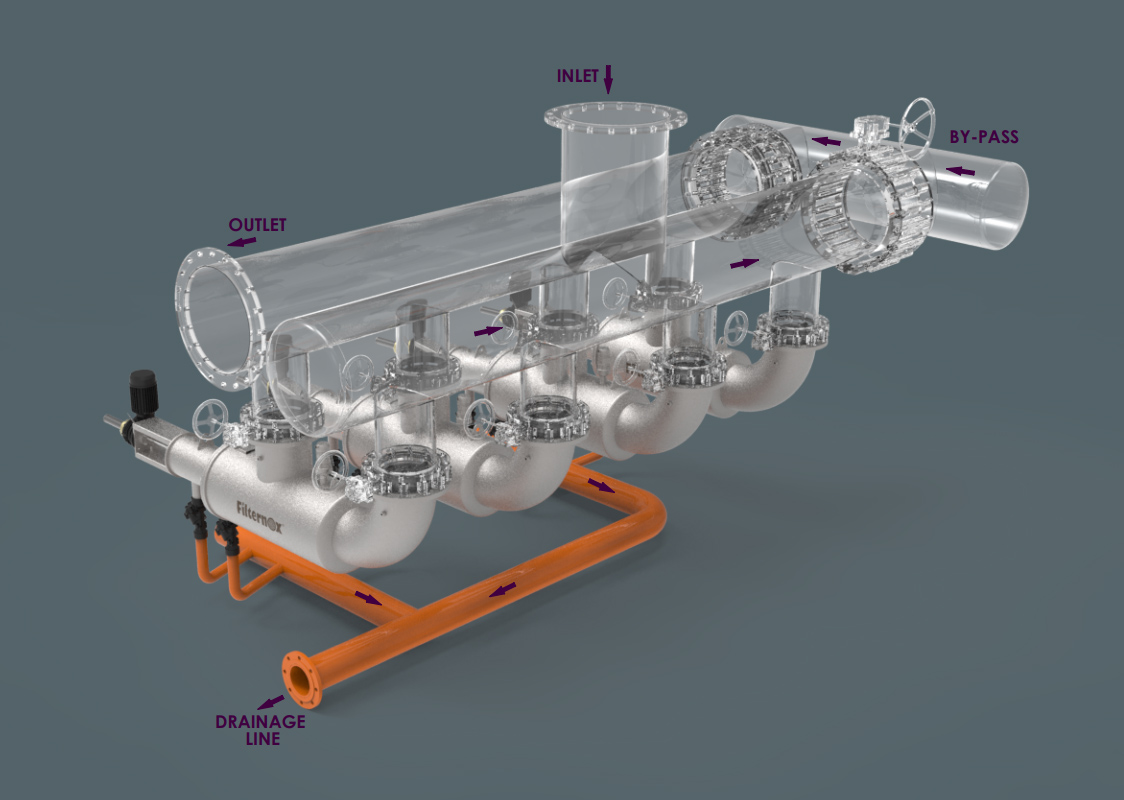

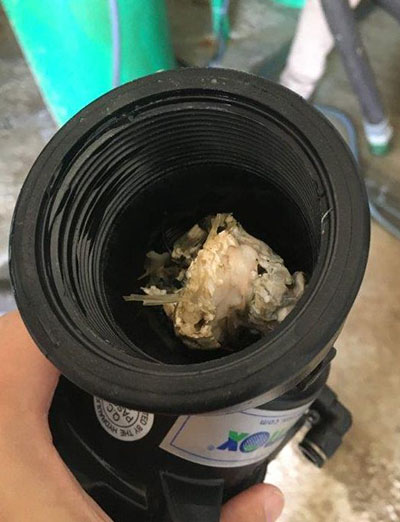

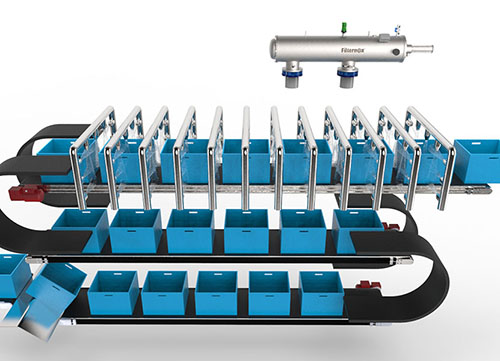

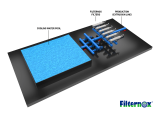

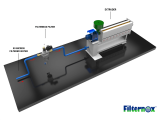

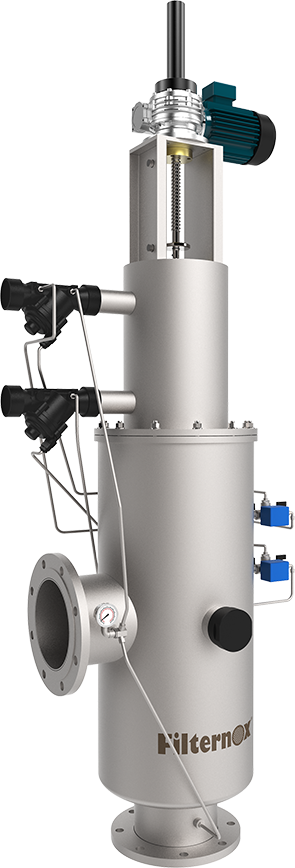

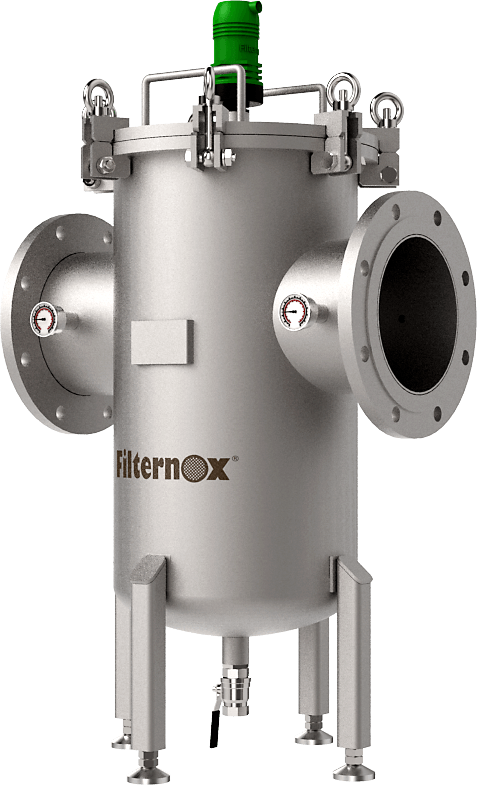

Filternox® filters are successfully integrated in reusable container(tray, crate, trolley, pallet, bin, etc.) washers and extend the life of such cleaning and disinfection systems by protecting nozzles from blockage caused by dirt and many types of contaminants.

Filternox® filters are successfully integrated in reusable container(tray, crate, trolley, pallet, bin, etc.) washers and extend the life of such cleaning and disinfection systems by protecting nozzles from blockage caused by dirt and many types of contaminants.

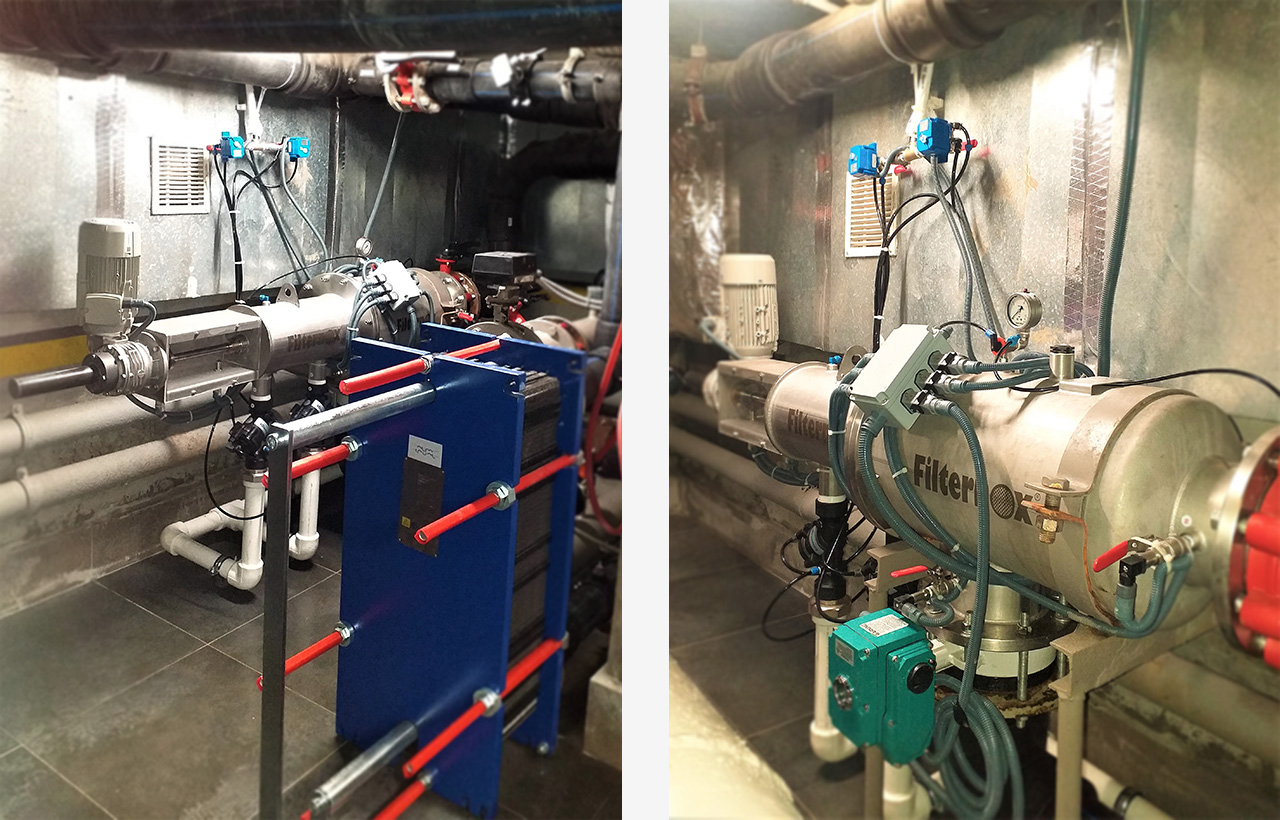

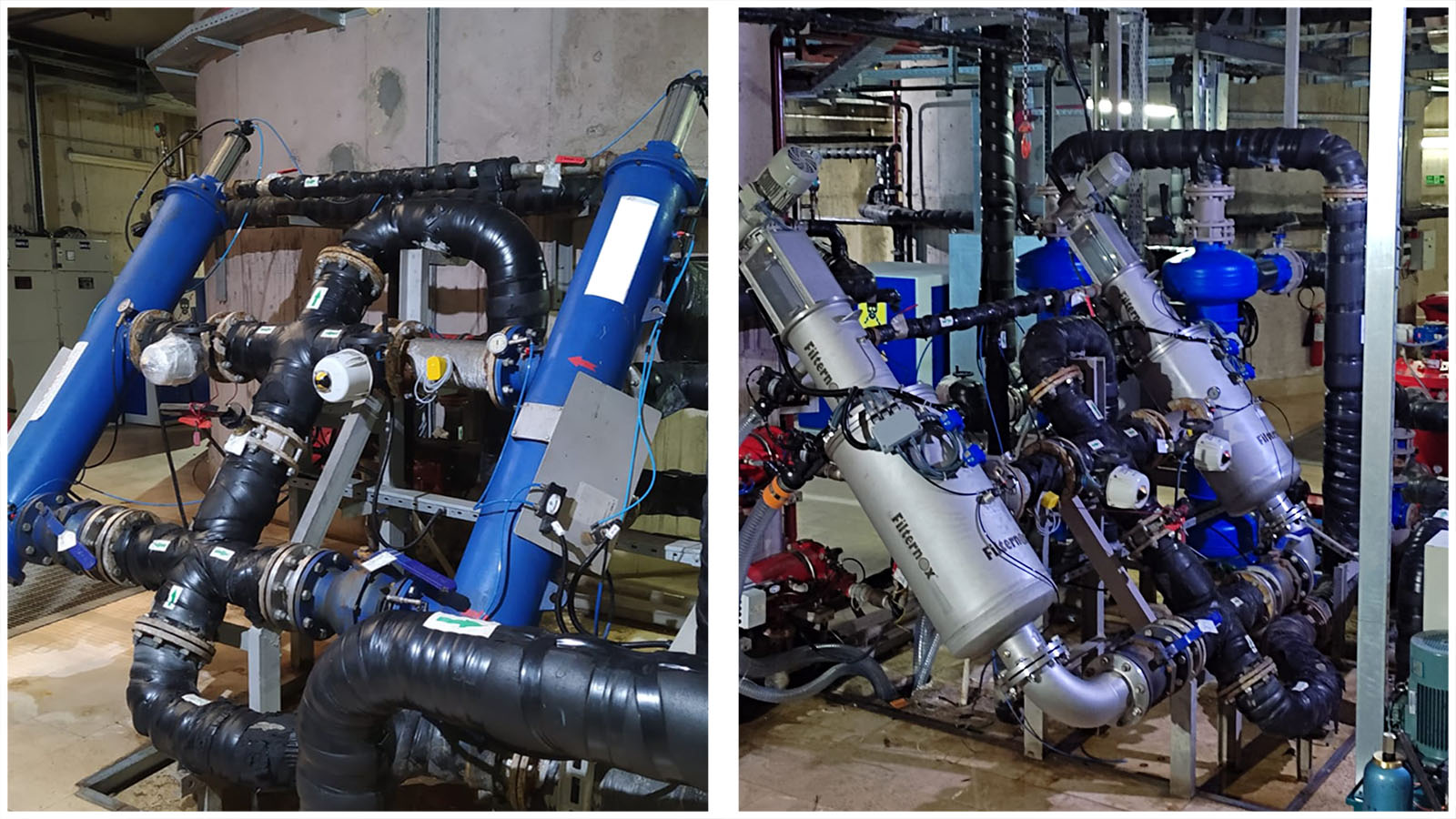

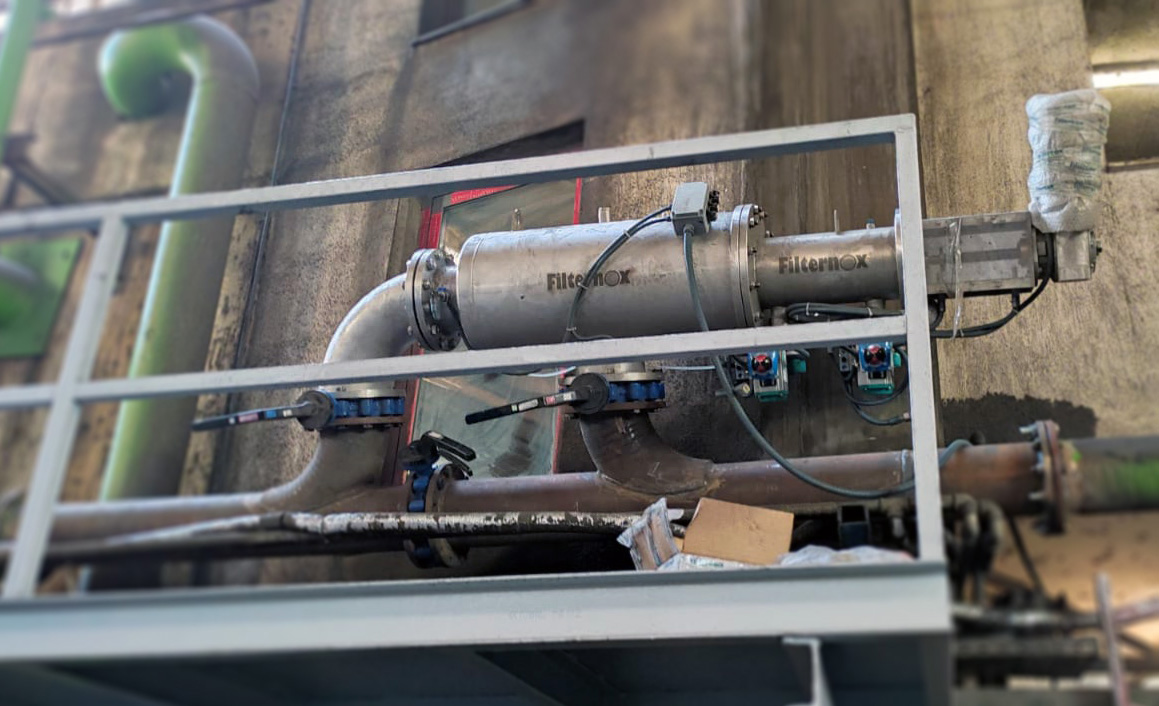

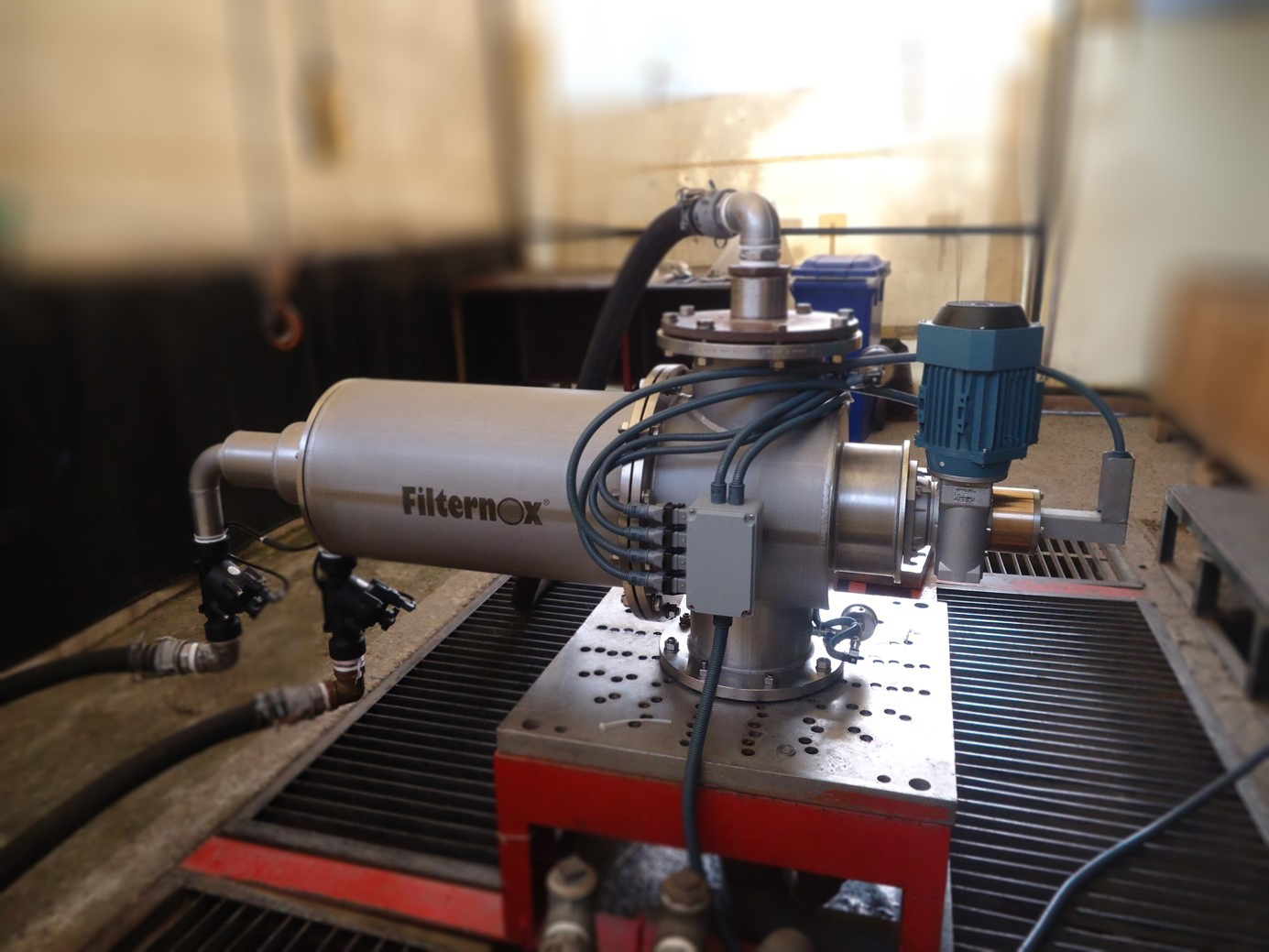

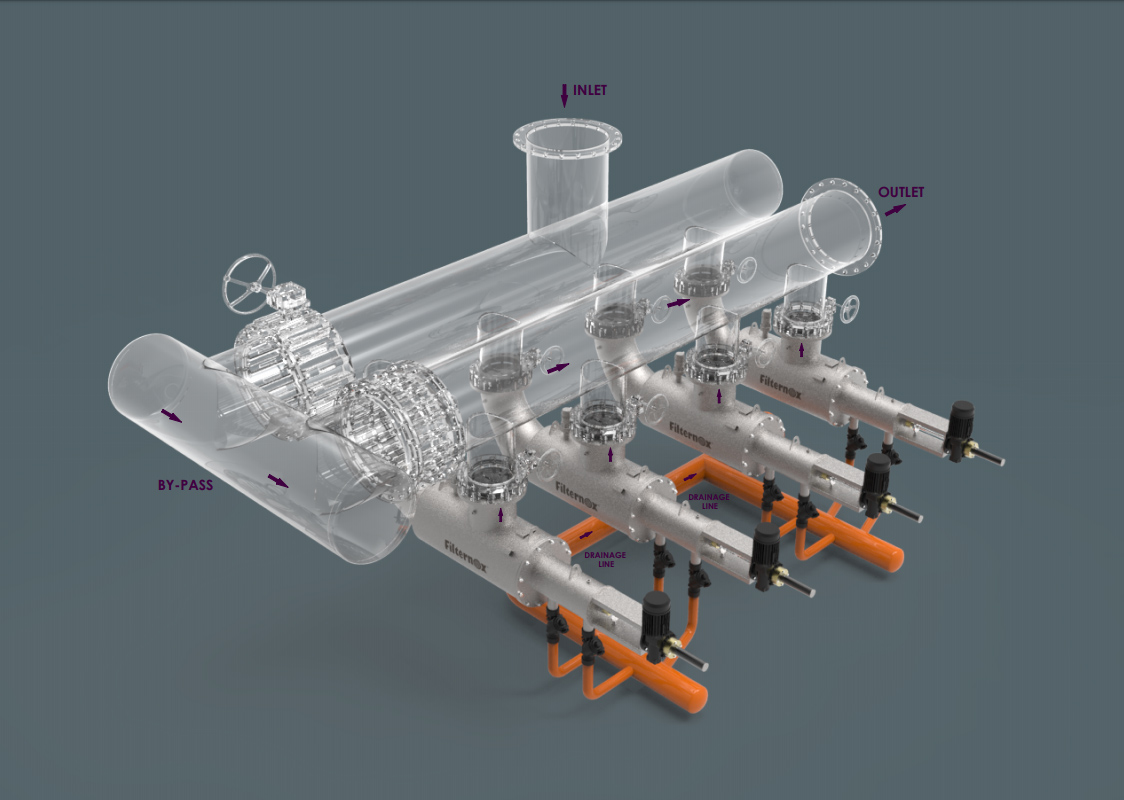

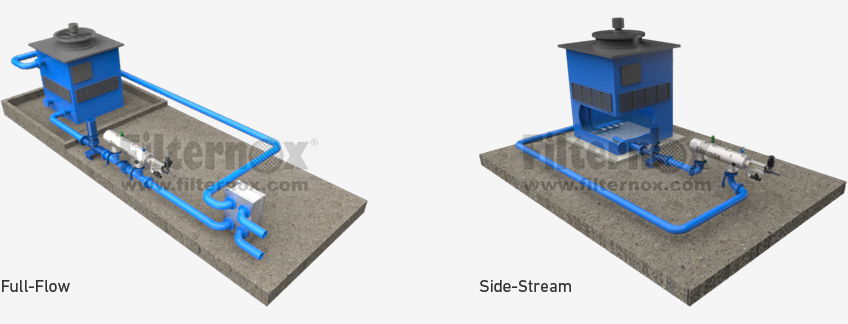

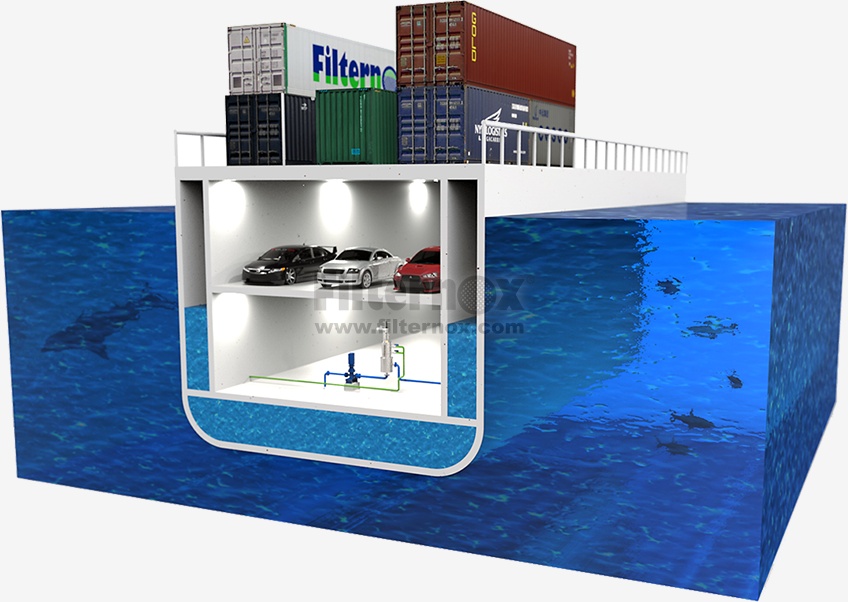

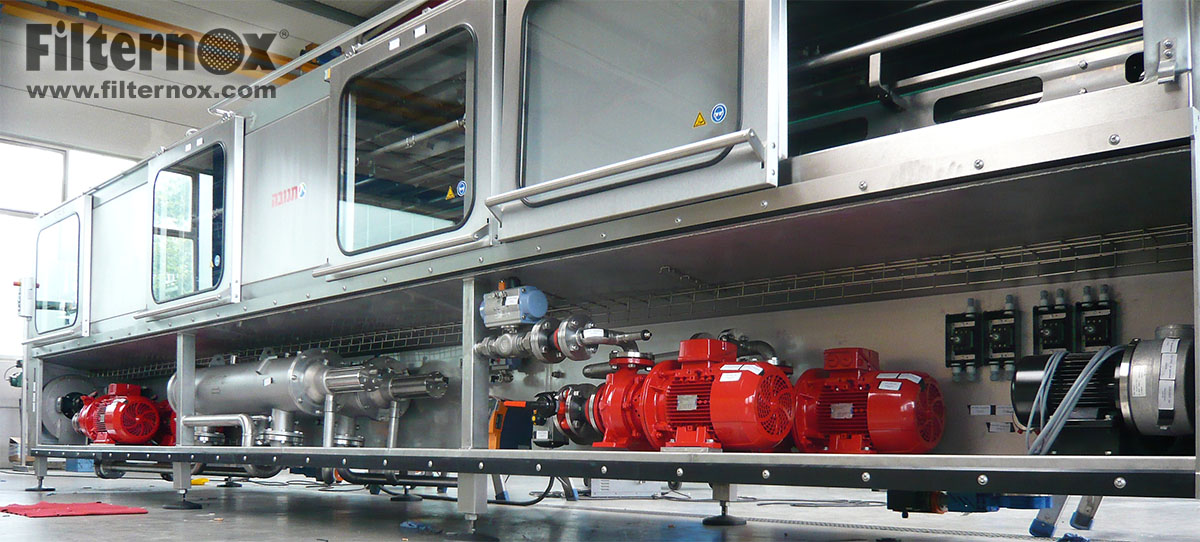

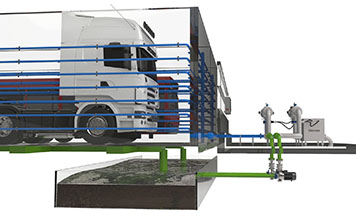

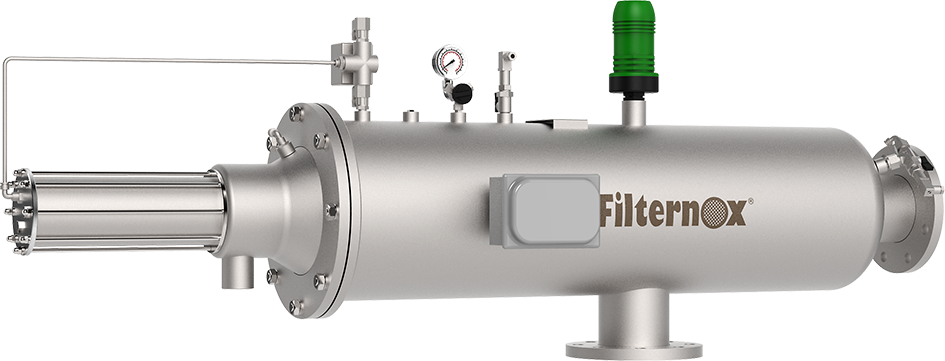

Filternox® filters are widely used in the automotive industry as well as in different processes and units of many industrial plants such as iron and steel, paper, textile, plastic and chemistry.

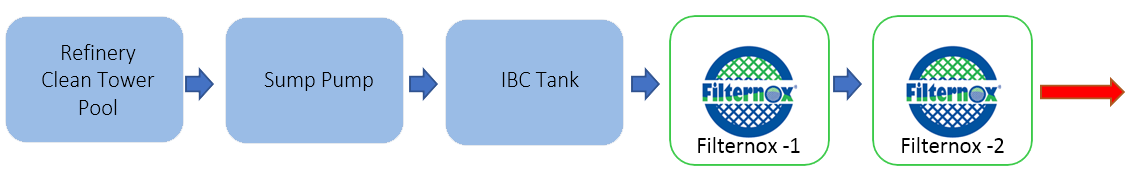

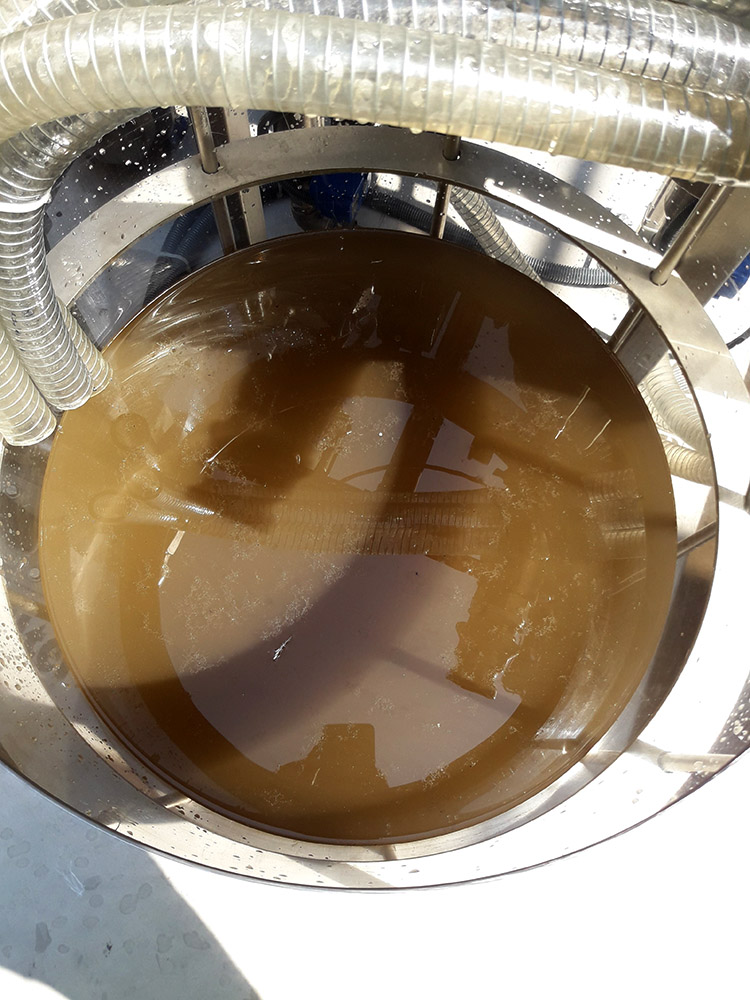

Filternox® filters are widely used in the automotive industry as well as in different processes and units of many industrial plants such as iron and steel, paper, textile, plastic and chemistry. The vehicles are contaminated with sand, gravel, silt and other pollutants during the various tests carried out at open-air environment after their production. Following these tests, the vehicles are subjected to a leakage test. For that, the water sprayed on the vehicle is contaminated with pollutants on it and collected in a pool. The water in the pool is fed back to the sprinkler system to provide a continuous circulation.

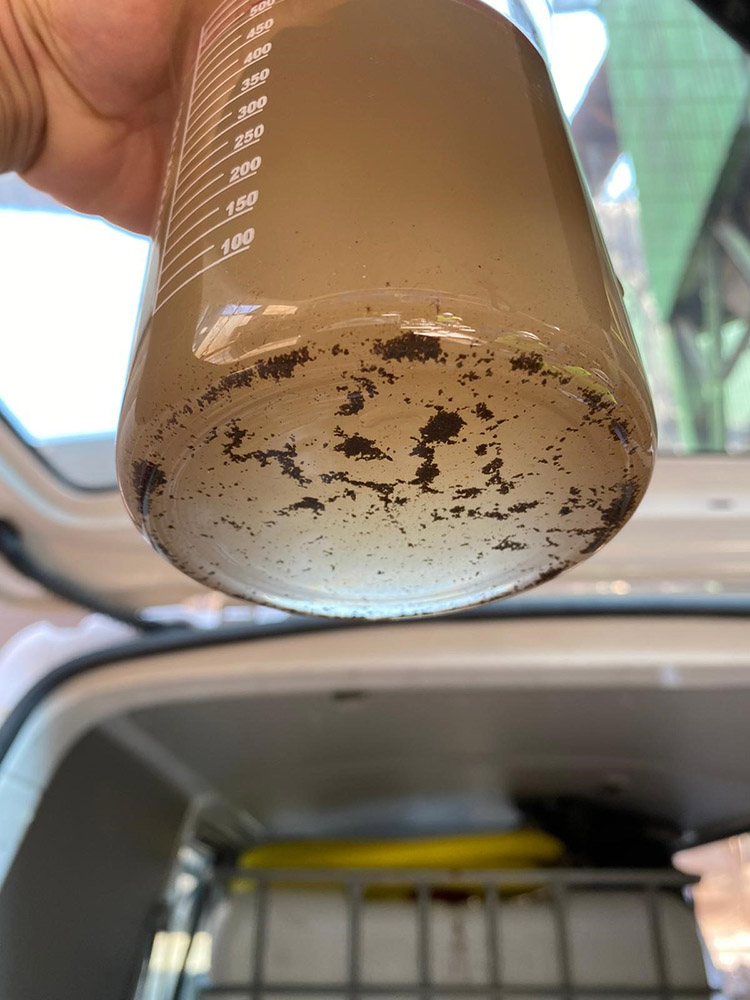

The vehicles are contaminated with sand, gravel, silt and other pollutants during the various tests carried out at open-air environment after their production. Following these tests, the vehicles are subjected to a leakage test. For that, the water sprayed on the vehicle is contaminated with pollutants on it and collected in a pool. The water in the pool is fed back to the sprinkler system to provide a continuous circulation.

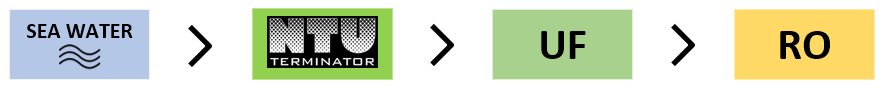

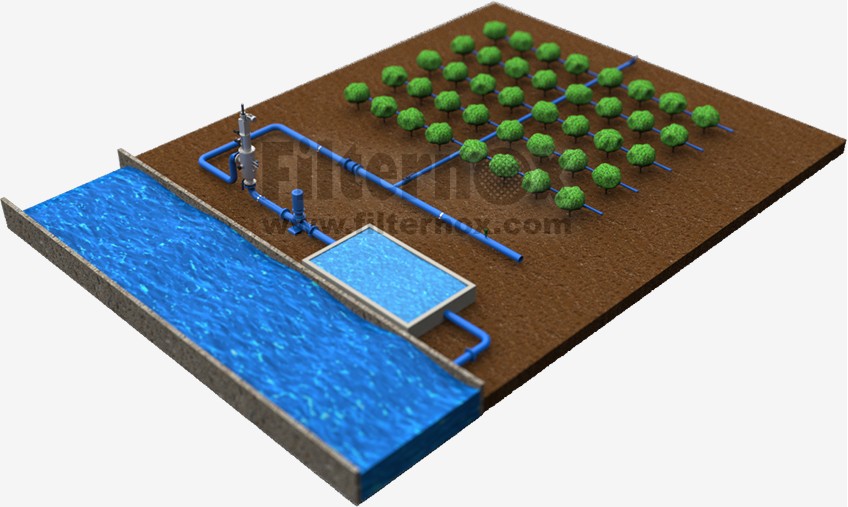

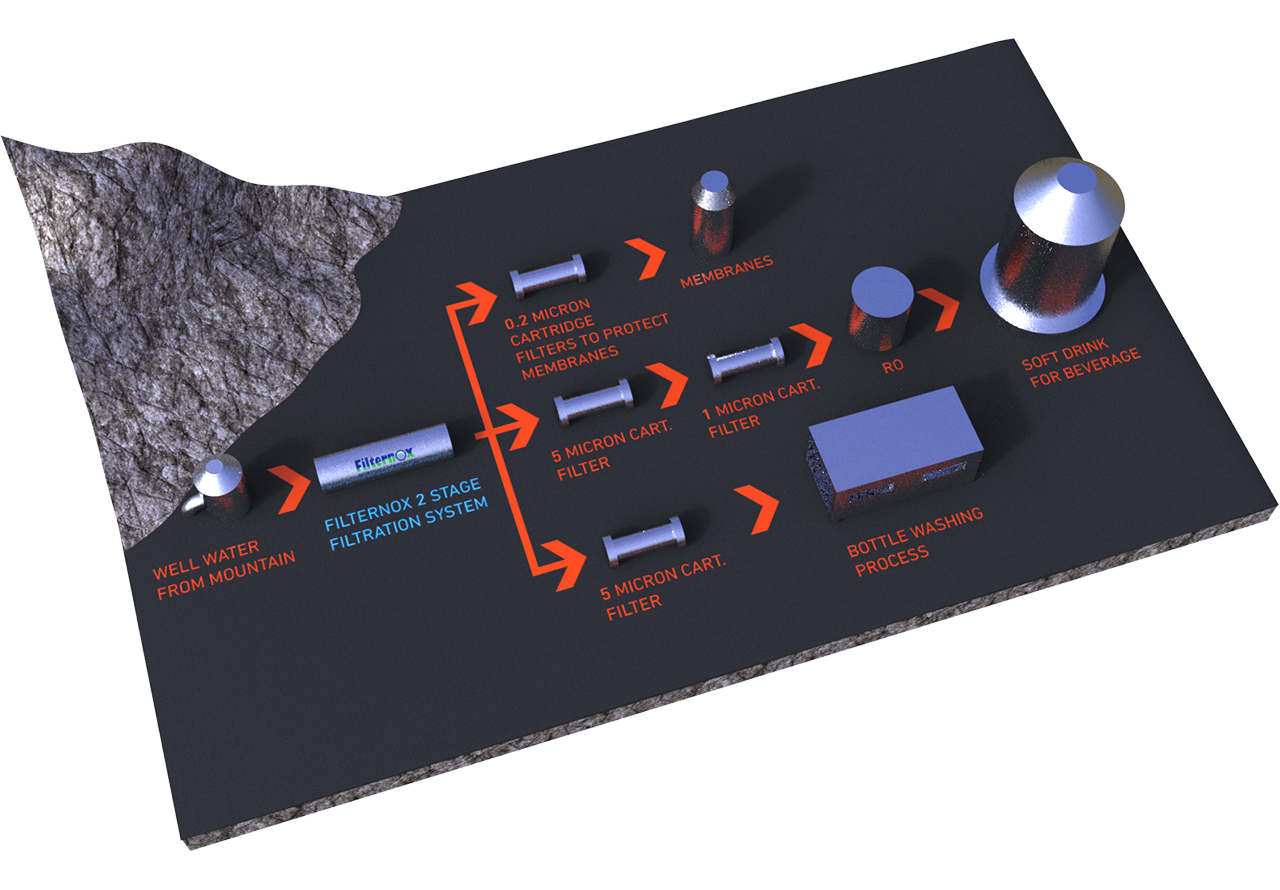

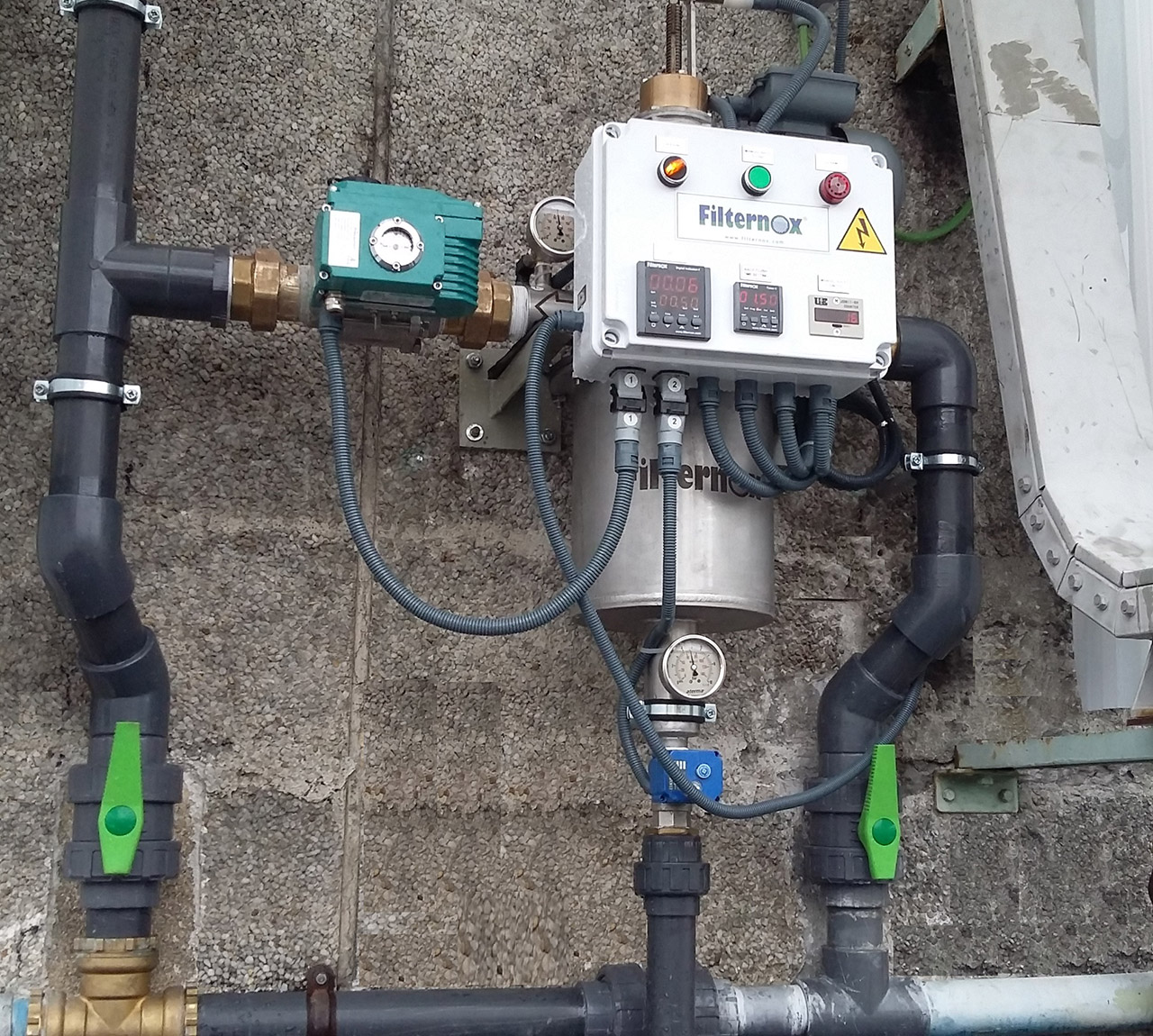

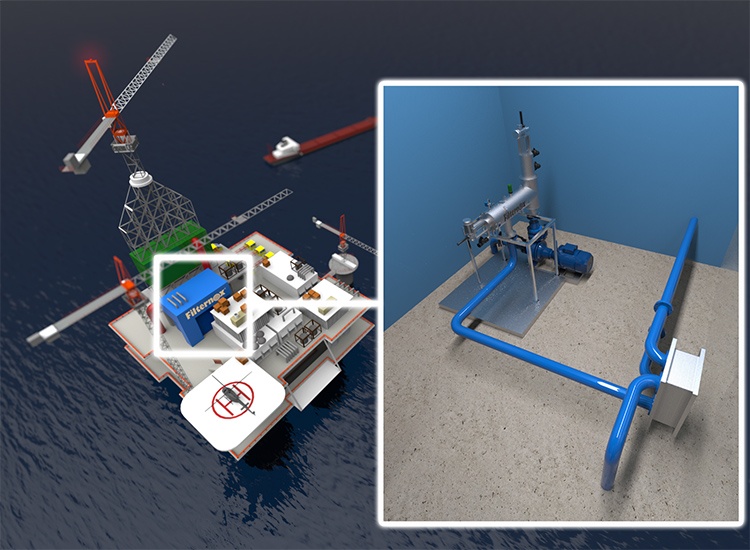

Filtration of well water is becoming one of the most important forms of filtration in the environmentally changing world. High carbon emissions along with the increasing greenhouse effect have dramatically reduced underground water supplies. This in turn, increases the amount of both organic and inorganic contaminants in the well water that is pumped through pipelines and other systems, creating the need of filtering well water.

Filtration of well water is becoming one of the most important forms of filtration in the environmentally changing world. High carbon emissions along with the increasing greenhouse effect have dramatically reduced underground water supplies. This in turn, increases the amount of both organic and inorganic contaminants in the well water that is pumped through pipelines and other systems, creating the need of filtering well water.